DESCRIPTION

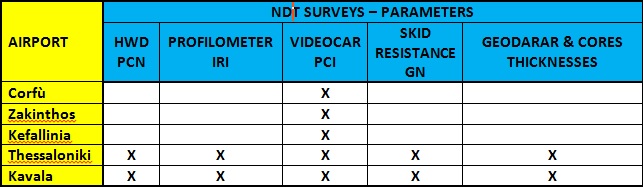

Between January and April 2017 RODECO Group conducted a series of high-performance surveys on 5 airports managed by Fraport AG in Greece. The airports examined are shown in the following table, and for each airport the type of NDT tests performed is specified.

The purpose of the study was to define the current situation of the pavements of the airports examined, in order to be able to determine a PMS (Pavement Management Systems) for the scheduling of maintenance interventions in a 5-year time window. Fraport AG needed this type of evaluation after taking over the management of these airports in Greece, in order to be able to allocate a suitable budget for the redevelopment of the infrastructures.

SURVEY OF THE SURFACE DISTRESSES – PCI INDEX

A survey was carried out at all airports with the Videocar-ADE system on all pavements, in order to determine the type, severity and quantity of surface deteriorations present at the time of the surveys, and consequently the PCI index for each Sample Unit.

Starting from the quantity and severity values of the distresses, it was possible to determine the PCI (Pavement Condition Index) for all the Sample Units identified, as shown in the following diagram. PCI values have been divided into 3 classes:

PCI ≤ 55 pavements in critical conditions;

55 < PCI ≤ 70 pavements in sufficient conditions;

PCI > 70 pavements in optimal conditions.

For each identified deterioration, a sheet was also produced, relating to the analyzed area, in which the following were highlighted:

The various severities found (critical in red, sufficient in yellow, slight in green) in each Sample Unit;

The total quantities for each Sample Unit.

The raveling sheet is shown as an example: the areas are characterized by a pair of values (letter-number) which allows identification on the map, in addition to georeferencing; some representative images of the deterioration have also been reported.

BEARING CAPACITY SURVEY –PCN (Pavement Classification Number) INDEX

As regards the bearing tests, they were performed at the network level on all the pavements of the Thessaloniki and Kavala airports, in order to have an overall overview of the situation and to determine the areas where the pavement was most lacking, to foresee structural requalification interventions to plan for the future. The tests were therefore performed, as reported in the FAA AC regulation n.150 / 5370-11b “Use of Nondestructive Testing in the Evaluation of Airport Pavements” on the following alignments:

± 3 m to the axis;

± 6 m to the axis;

± 20 m to the axis (only for Runways).

The results of the HWD tests were furnished in table and graphical format, for easy viewing by the customer, together with the raw deflection data. For the calculation of the PCN index, COMFAA was used as requested by the Customer.

SKID RESISTANCE SURVEY– GN (GRIP NUMBER) INDEX

The skid resistance surveys hase been conducted only on the Runways because they are the only areas where there is the aircraft rubber deposit, able to reduce the friction in the touch-down zone.

The tests were performed with the GripTester equipment, following the recommendations provided by ICAO Annex 14 regarding the execution of the tests on the following alignments (and at predefined speeds):

± 3 m at 65 Km/h;

± 6 m at 65 Km/h;

± 3 m at 95 Km/h;

± 6 m at 95 Km/h.

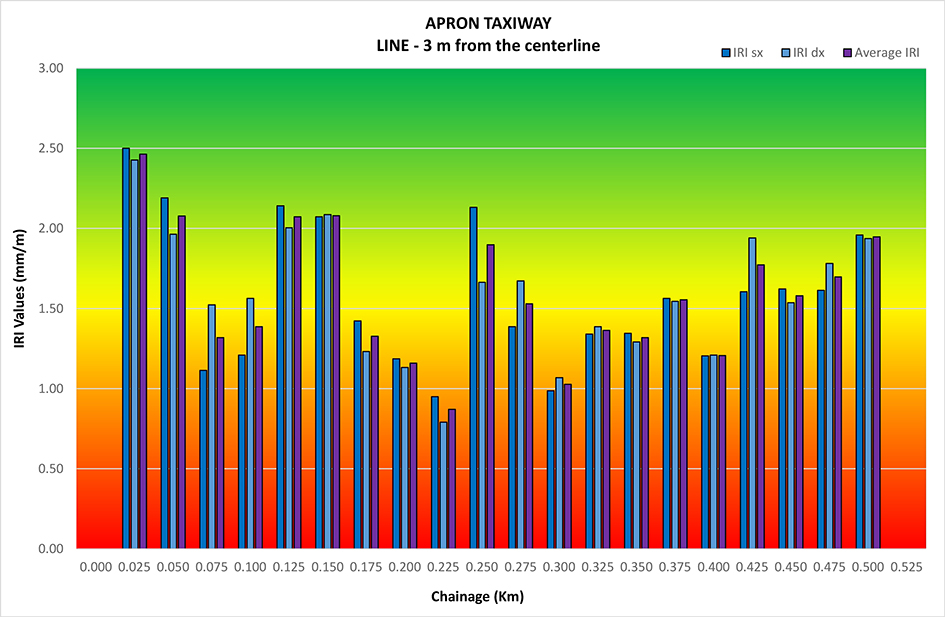

ROUGHNESS SURVEY –IRI (International Roughness Index) INDEX

The Laser profilometer survey, for the detection of the IRI and BBI (Boeing Bump Index) indices, have been carried out following the FAA AC n.150/5380-9 “Guidelines and Procedures for Measuring Airfield Pavement Roughness” on the alignements:

Centerline;

± 3 m to the centerline;

± 6 m to the centerline.

The results of the roghness tests were returned in tabular and graphical format, for easy viewing by the customer.

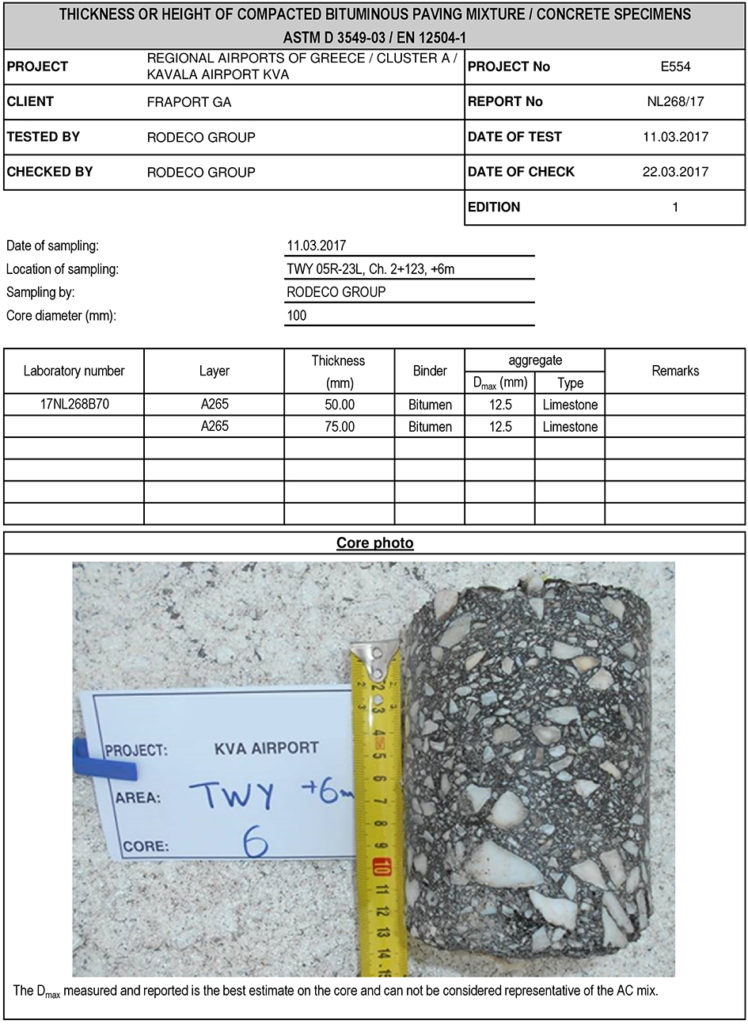

DETECTION OF LAYER THICKNESSES BY GEORADAR & CORES SURVEY

The georadar surveys, carried out on the pavements of the Thessaloniki and Kavala airports in collaboration with Namalab A.E., were performed to determine the stratigraphy of the various layers in order to obtain the input data for the calculation of the bearing capacity. In order to calibrate the radar signal in the best possible way, coring was also performed on the various investigated areas: an example of coring result is shown below.

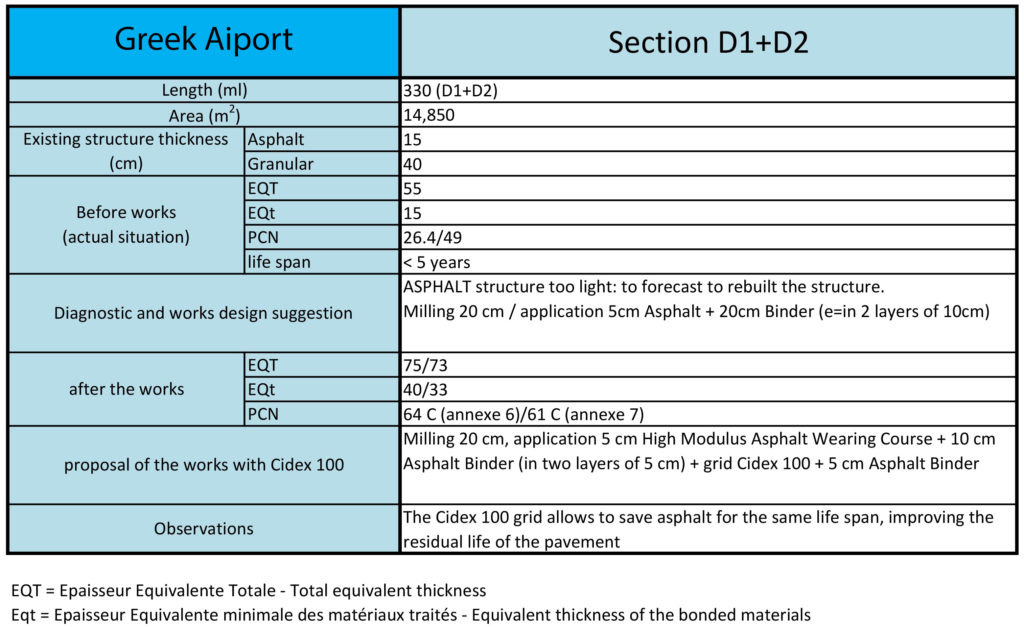

P.M.S. (PAVEMENT MANAGEMENT SYSTEM)

The RODECO Group, in addition to checking the current state of the pavements, also suggested various types of maintenance interventions to be applied in the medium/short term in order to restore those critical issues highlighted during the surveys.

Depending on the conditions of the pavements, interventions were proposed as follows:

Preventive maintenance, with the aim of preserving the current condition and prolonging the residual and functional life of the pavement over time;

Partial/localized reconstruction and complete rehabilitation, to solve medium and long term problems of bearing capacity and roughness in more extensive areas.

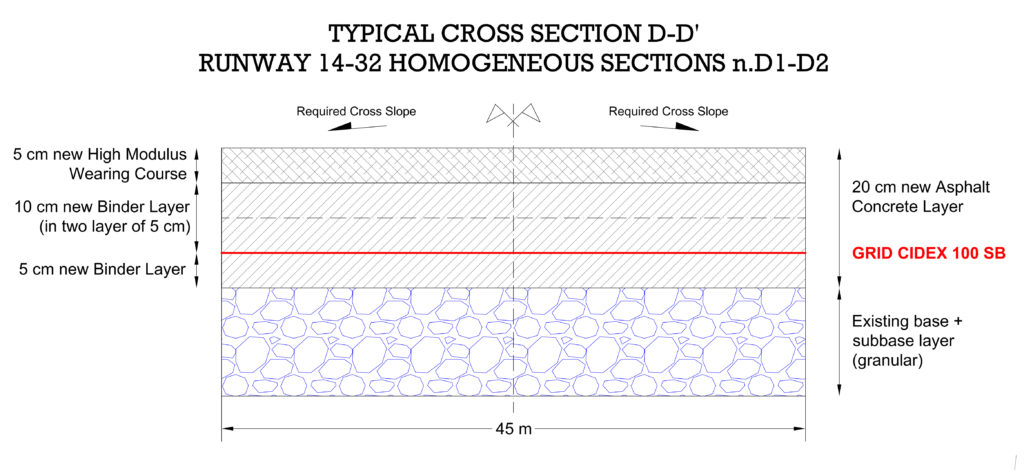

Starting from the data collected, it was possible to determine the homogeneous sections, for which the various maintenance strategies were identified considering the annual budget allocated by the Client and the various types of intervention usually applied in Greece. In the case of reconstruction of the pavement, as prescribed by the Customer, the FAARFIELD 1.41 software was used. The proposed reconstruction interventions have been sized in order to save on the total budget (reducing the total thickness of the asphalt layers), guaranteeing the same bearing parameters: in this context, the use of the CIDEX 100 geogrid has proven to be fundamental in order to extend the residual life of the pavements, acting as reinforcement for the asphalt.

The most important treatment suggested as preventive maintenance are the following:

Waterblasting removal of rubber deposit on the touch-down zone, able to don’t damage the pavement surface restoring friction and macrotexture;

Crack sealing on asphalt pavements, in areas with good results of bearing capacity and roughness, but having some problems about surface distress and aging;

Surface treatment at medium-long term (rejuvenating application and slurry seal), with the aim of preserve the good/optimal pavement conditions during the time;

On the rigid pavement: joint&crack sealing, partial-depth patching and surface treatment focused on the raveling & FOD stopping.