ADE (AUTOMATIC DISTRESS EVALUATION) TECHNOLOGY

The ADE (Automatic Distress Evaluation) technology has benne developed by RODECO Group, in order to collect videos and/or images of pavement distresses for the evaluation o the PCI (Pavement Condition Index) parameter.

There are 4 instrumental data survey areas composing the ADE System:

Integrated positioning system (Encoder);

GPS system;

Video-acquisition platform;

Acquisition & Processing software.

Focalizing on the video-acquisition platform, The ADE-VIDEOCAR vehicle will be equipped with a video acquisition system based on three high definition cameras connected to the computer and the photo stored on the hard disk.

The acquisition takes place in two ways:

real-time sending of video acquisition to the computer, and recording on the hard disk;

synchronization with encoder and GPS signal.

The 3 cameras will be positioned, with respect to the vehicle’s running direction, in the following position:

one camera in front of the car, to record front view with a wide viewing angle;

two cameras with an angle of 90° related to the pavement surface: in this way, it’s possible to have a complete view of the pavement for a total width of about 3/4 meters.

Acquisition Software

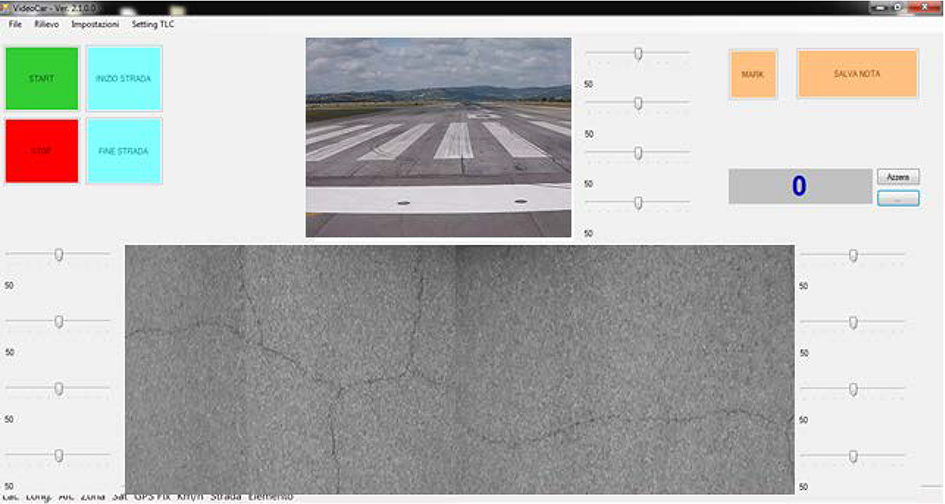

The acquisition software was developed entirely by RODECO Group to manage the acquisition of pictures from the cameras together with the localization systems (GPS and Encoder).

The software is designed to manage three cameras (but it’s configurable in order to satisfy the customer’s needs) and is equipped with graphic windows, from which the operator can control and change the quality of the acquisition with simple software commands.

The software, via serial port and USB, synchronizes the localization devices (odometer and GPS) associating to each video the reference progressive value, the geographic coordinate (NMEA string in WGS84 coordinates) and the time.

The operator, after a careful initial setting and calibration procedure of the cameras based on the environmental working characteristics, will only have to supervise the process without intervening in any way on the acquisition procedures, except in exceptional cases, such as a change of brightness etc.

If necessary, real-time acquisition of special events (start and end of the road, milestones, notes, etc.) is possible.

The odometer calibration, which must be performed according to quality procedures, is carried out directly by the software with special tools dedicated. Images will be stored in the hard disk in *.jpg format; using a software tool, it’s possible to process the GPS data and obtain the axles of each detected line, to upload them on CAD files.

Post-Processing Software

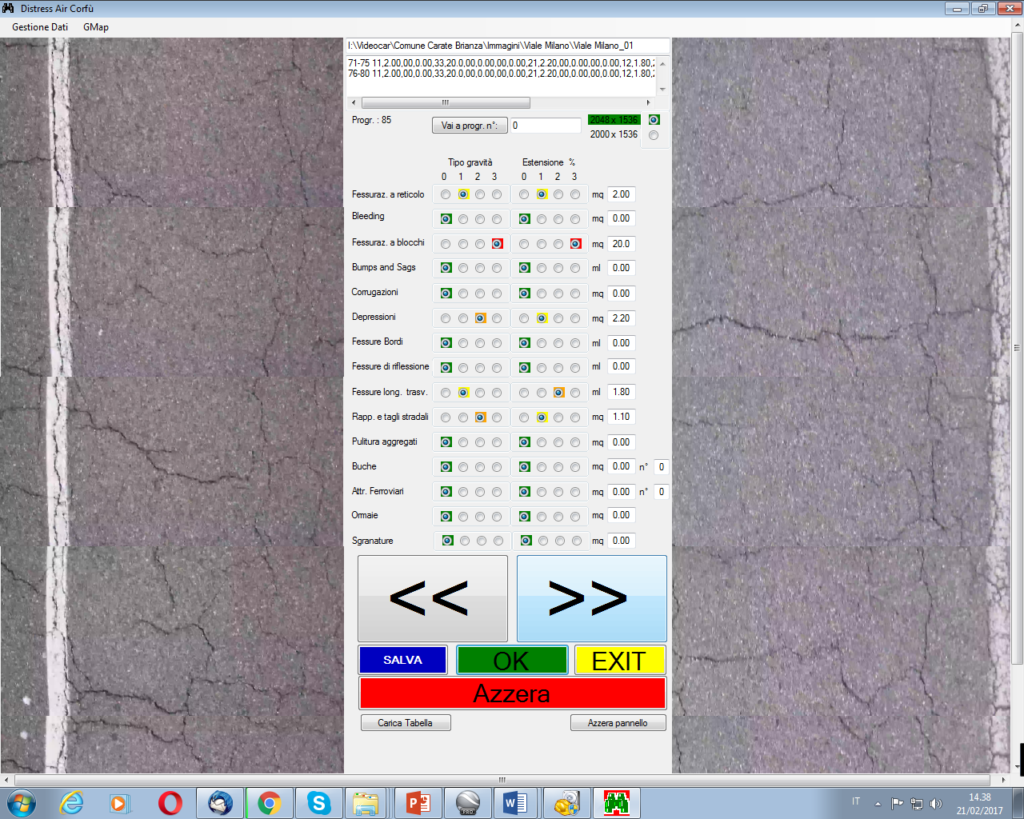

The post-processing software, developed by RODECO and used by our technicians, permits to evaluate the main distresses reported in the ASTM D5340-12, using a code, as reported in each excel files of the surveyed lines.

The quantities of the detected distresses are analyzed evaluating also the distress severity; the severity and the extension rating are linked together in a code, as follow:

00: no distress detected;

11: low severity and low extension;

12: low severity and medium extension;

13: low severity and high extension;

21: medium severity and low extension;

22: medium severity and medium extension;

23: medium severity and high extension;

31: high severity and low extension;

32: high severity and medium extension;

33: high severity and high extension.

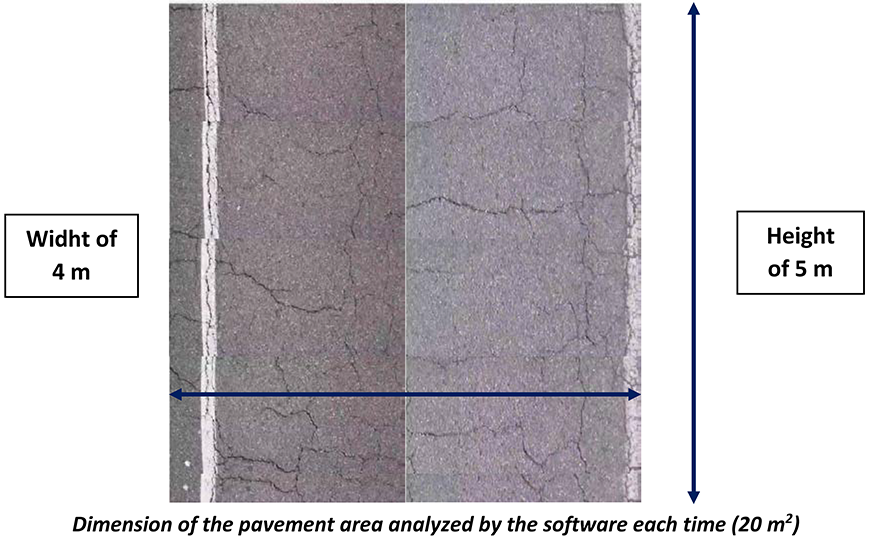

The images are processed merging 5 file together: in this way, it’s possible to process about 20 m2 of pavement each time (the global width of the 2 rear camera frames is 4 m, and the height is 1 m). The operator have to insert manually the quantity and the severity for each detected distress with the software mask, estimating them from the pictures.

The output of the image analyzing software is an excel file, with the results of quantity and severity for each detected distress, processed every 5 m of pavement. The file will be insert in an excel macro in order to process the PCI for the given sample units.